Wdnld/Shutterstock

Wdnld/Shutterstock

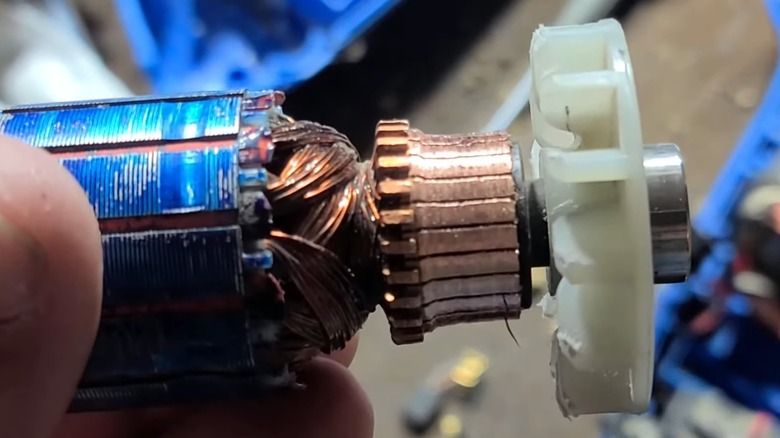

When choosing a modern power tool, there are many factors to consider before buying. The power source, brand, and price are arguably the most important, but there's one more key distinction to make: brushed or brushless. This comes down to the tool's inner workings and whether it uses carbon brushes, which make contact with the tool's commutator to deliver electricity to the motor. Thus, the rotor spins and the tool functions as expected. Unfortunately, time is not kind to this setup; prolonged use can damage the motor.

The very design of a brushed motor is what ultimately leads to its downfall after years of use. The friction between the carbon brushes and the commutator wears down both, since they're always in direct contact with nothing to reduce friction. Eventually, they'll wear down so much that when the drill's trigger is pressed to create the connection, they simply won't make contact with one another. The drill will cease to function. For this reason, many recommend that, from brands like DeWalt, some tools should always be purchased brushless to ensure a longer lifespan.

While they may work for some time, clearly brushed motors are on borrowed time from the beginning. Thus, one has to wonder, how can brushed power tools be prolonged, and when they wear out, can they be repaired?

Combatting the breakdown of brushed power tool motors

Catus Maximus/YouTube

Catus Maximus/YouTube

To get the most from a brushed power tool, the key is to take proper care of it so it doesn't break down any quicker than it needs to. Some of these maintenance tips are quite simple, such as keeping your tools clean and storing them in appropriate, manufacturer-recommended environments — within safe temperature and moisture levels and out of direct sunlight. Others pertain specifically to when the tool is in use. It's never good to overwork a power tool, either running it too hard for too long or trying to force it through jobs it's not equipped for. You also don't want to subject your tool to a fluctuating power source, like a dying battery, a wall outlet with poor wiring, or an outlet prone to surges. These contribute to internal damage.

If it's too late to implement these tips, there's more you can do once a brush tool breaks down. While carbon brushes can't be repaired, they can be replaced. So long as you know what you're doing, you have the right parts and tools for the job, and you take the proper safety precautions, this shouldn't take too long. You also need to be aware of the type of brushed motor you have, as they have different layouts and components that will affect how repairs are done. Of course, if you're not comfortable with such tasks, there's no shame in shopping around for replacement tools instead, avoiding the cost of parts and the risk of injury from a botched repair.

There are plenty of power tools out there that don't require much maintenance, though brushed power tools aren't quite among them. They need to be well-maintained to last as long as possible, fending off their self-imposed demise.